In modern industrial and infrastructure settings, steel gratings play a pivotal role in balancing structural strength, ventilation, drainage, and safety. These elements are commonly found in walkways, platforms, drainage covers, mezzanine floors, and more. At Aparna Rollform, we deliver precision-engineered gratings to meet rigorous industrial demands. In this post, we explore the different types of steel gratings and where each type shines in real-world applications.

What Is a Steel Grating?

A steel grating is an assembly of load-bearing bars and cross bars (or cross rods) welded, pressure-locked, or mechanically locked to create a grid structure. The result is a surface that can support loads while permitting the passage of light, air, fluids, or other small elements. The open grid structure also helps reduce weight compared to solid plating while maintaining strength.

Aparna Rollform’s gratings are designed for high load capacity, corrosion resistance, customization, and durability. On our Gratings product page, we define key features such as load-bearing capacity, versatility, and customization options for steel, stainless steel, and aluminum variants.

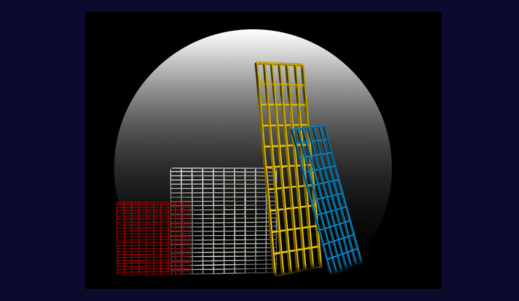

Major Types of Steel Gratings

Here are the most common types used in industrial and commercial projects:

1. Welded Steel Gratings

- Construction: Load bars and cross bars are welded at every intersection, creating rigid and durable panels.

- Advantages: High strength, excellent load handling, minimal deflection, uniformity.

- Typical Applications: Heavy-duty industrial walkways, flooring in factories, mezzanine and platform decks.

2. Pressed / Lock-Type Gratings

- Construction: Bars interlock under pressure; cross bars are pressed and locked rather than welded.

- Advantages: Cleaner appearance, less welding heat distortion, good for medium loads.

- Typical Applications: Walkways, access pathways, mild industrial settings.

3. Pressure-Locked / Swaged Grating

- Construction: A mechanical process where cross bars are swaged or pressed into load bars to lock them in place.

- Advantages: Good uniformity, reduced sharp edges, suitable for architectural uses.

- Typical Applications: Architectural flooring, facades, decorative applications.

4. Serrated / Anti-Slip Gratings

- Construction: Surface of load bars is serrated (toothed) to provide extra grip.

- Advantages: Enhanced slip resistance under wet or oily conditions.

- Typical Applications: Outdoor walkways, stair treads, platforms exposed to moisture, hazardous environments.

5. Bar Gratings with Raised Surface (Rib or Raised Step)

- Construction: Bars are formed with raised features or steps for grip.

- Advantages: Combines load capacity with grip for sloped or greasy surfaces.

- Typical Applications: Stair landings, inclined walkways, loading ramps.

6. Expanded Metal Grating

- Construction: Sheet steel is slit and stretched into diamond-shaped openings.

- Advantages: High open area, low weight, good for light-to-medium loads, economical.

- Typical Applications: Walkways, flooring in lightweight structures, decorative facades.

7. Welded Mesh Gratings / Wire Mesh Decking

- Construction: Welded wire mesh panels used in composite floor systems.

- Advantages: Lightweight, flexible, often used in combination with concrete topping.

- Typical Applications: Raised floor decking, industrial mezzanines, ventilation floors.

Applications of Steel Gratings

Below are typical scenarios where different gratings are applied:

Walkways, Platforms & Mezzanines

Welded gratings are preferred for heavy duty walkways in industrial plants, providing safety, stability, and durability. The rigid structure ensures minimal deflection under load, crucial for worker safety.

Stair Treads & Landings

Serrated or raised-bar gratings are standard on stairs and landings, especially outdoors. They offer slip resistance even under wet, oily, or icy conditions.

Drainage Covers & Trench Covers

Expanded metal or light-weight welded gratings are used for drainage grates over channels. Their open grid lets water flow while supporting traffic safely.

Platform & Catwalk Structures

Platforms with machinery often employ welded gratings to provide rigid access across complex layouts. The open nature also allows illumination, ventilation, and ease of movement for cables or pipes.

Industrial Flooring & Flooring Systems

Wire mesh or welded mesh panels combined with concrete topping form composite floor systems in warehouses or plants. Grating provides reinforcement and structural support.

Architectural & Aesthetic Uses

Press-lock or pressure-locked gratings, sometimes in stainless steel or decorative metals, appear in facades, sun-shades, balcony decking, or terraces where aesthetics and function merge.

Offshore & Marine Structures

Serrated and galvanized gratings are used on ship decks, offshore platforms, walkways, and gangways where harsh weather and corrosive sea environments demand superior durability.

Advantages of Choosing Aparna Rollform Gratings

Aparna Rollform offers gratings crafted with precision and quality, part of their roll-form portfolio that includes cable management systems, false ceiling sections, uPVC reinforcements, and finishing processes.

Some standout advantages:

- Customization: Tailored dimensions, bar spacing, openings, and finishes to match project specifications.

- High Load Bearing & Structural Integrity: Engineered to support heavy industrial loads.

- Durable Surface Finishing: Options like hot-dip galvanizing and powder coating protect against corrosion in harsh conditions.

- Versatility Across Sectors: From industrial facilities and data centers to commercial buildings and transportation infrastructure.

- Efficient Delivery & Support: As a roll form specialist, Aparna emphasizes fast delivery and responsive customer support.

Future Trends & Innovations in Steel Gratings

- Composite Gratings: Steel grating combined with fiberglass or polymer elements for reduced maintenance and corrosion resistance.

- Laser-Cut Custom Patterns: For architectural and signature designs.

- Smart Gratings / Embedded Sensors: Monitoring load, deflection, or structural health in real time.

- Eco-Friendly Coatings & Green Surface Treatments: Low-VOC coatings, recyclable galvanizing, or self-healing coatings.

- Modular & Interlocking Systems: Easier installation and reconfiguration in evolving plant environments.

Conclusion

Steel gratings are indispensable in industrial construction, providing strength, ventilation, drainage, slip resistance, and structural integration. Each variant—welded, press-lock, serrated, expanded, or wire mesh—brings its own set of advantages tailored to specific applications. For heavy-duty walkways, welded gratings shine; for aesthetic facades, press-lock options are ideal; for wet or slippery zones, serrated surfaces are non-negotiable.

At Aparna Rollform, we deliver precision-engineered gratings that meet the full spectrum of industrial demands—backed by customization, surface finishing, and timely support. Whether you’re designing a data center, factory, transportation hub, or commercial complex, choosing the right grating type is critical for safety, performance, and longevity.