In modern electrical infrastructure, cable management plays a vital role in ensuring safety, efficiency, and long-term system reliability. As industrial and commercial installations grow more complex, the need for robust cable support systems becomes increasingly important. Among the various cable management solutions available today, ladder cable tray systems have emerged as the preferred choice for high-load and heavy-duty installations.

At Aparna Rollform, we design and manufacture ladder cable tray systems that meet the demands of power-intensive environments, ensuring strength, durability, and compliance with industry standards.

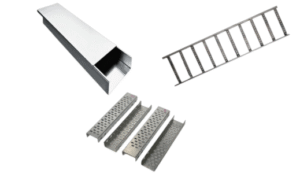

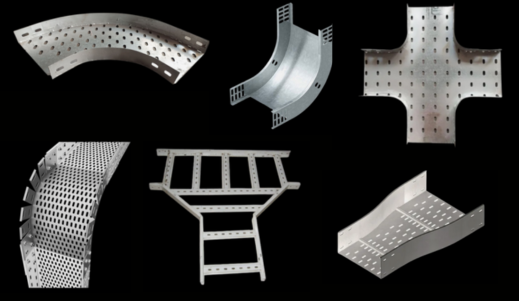

Understanding Ladder Cable Tray Systems

Ladder cable tray systems consist of two longitudinal side rails connected by transverse rungs, resembling a ladder structure. This design allows cables to be laid, supported, and secured efficiently over long spans while handling significant cable weight.

Unlike perforated or solid-bottom trays, ladder trays offer superior load-bearing capacity and ventilation, making them ideal for industrial applications where large, heavy cables are involved.

Superior Load-Bearing Capacity

One of the primary reasons ladder cable trays are ideal for high-load installations is their exceptional strength. The ladder-style construction evenly distributes the cable load across the rungs and side rails, minimizing stress concentration.

Key benefits include:

- Ability to support heavy power and control cables

- Reduced sagging over long spans

- Enhanced structural stability in demanding environments

This makes ladder trays suitable for industries such as power plants, manufacturing units, and large commercial facilities.

Efficient Heat Dissipation

High-load installations often involve power cables that generate heat during operation. Poor ventilation can lead to overheating, insulation damage, and reduced cable life.

Ladder cable tray systems provide excellent airflow due to their open design, allowing heat to dissipate naturally. This improves:

- Cable performance

- Electrical safety

- Overall system lifespan

Proper ventilation is especially critical in substations, data centers, and industrial electrical rooms.

Ideal for Long Span Installations

Ladder cable trays are designed to cover long spans with fewer supports, reducing installation complexity and structural costs. Their rigid construction ensures stability even over extended distances.

This feature is particularly advantageous in:

- Industrial sheds

- Warehouses

- Power transmission corridors

- Infrastructure projects

Fewer supports also mean easier maintenance and better accessibility.

High Durability and Corrosion Resistance

High-load installations are often exposed to harsh environments, including moisture, dust, chemicals, and temperature variations. Ladder cable trays manufactured by Aparna Rollform are available in:

- Pre-galvanized steel

- Hot-dip galvanized steel

- Powder-coated finishes

These finishes provide excellent resistance to corrosion, ensuring long service life even in challenging conditions such as industrial plants and outdoor installations.

Easy Cable Installation and Maintenance

The open ladder structure allows cables to be easily laid, removed, or modified without dismantling the entire system. This flexibility is essential for facilities that undergo frequent upgrades or expansions.

Maintenance advantages include:

- Easy inspection of cables

- Faster fault identification

- Simplified cable replacement

This reduces downtime and enhances operational efficiency.

Compliance with Industry Standards

Ladder cable tray systems are widely accepted in national and international electrical standards for high-load cable management. At Aparna Rollform, our ladder trays are manufactured with strict quality control to ensure:

- Dimensional accuracy

- Consistent load performance

- Compliance with relevant standards

This makes them a reliable choice for critical electrical infrastructure.

Applications of Ladder Cable Tray Systems

Due to their strength and versatility, ladder cable trays are widely used in:

- Power generation and distribution plants

- Oil and gas facilities

- Heavy manufacturing units

- Commercial complexes

- Metro rail and infrastructure projects

Their ability to support large cable volumes safely makes them indispensable in high-load environments.

Aparna Rollform’s Ladder Cable Tray Solutions

Aparna Rollform offers a comprehensive range of ladder cable tray systems designed for heavy-duty applications. Our trays are precision-engineered to deliver:

- High load-bearing capacity

- Long-lasting corrosion protection

- Easy installation and maintenance

With a focus on quality and performance, our solutions support complex electrical systems across industries.

Conclusion

Ladder cable tray systems are the ideal solution for high-load installations due to their superior strength, excellent ventilation, long-span capability, and ease of maintenance. Their robust design ensures safety, durability, and efficiency in demanding electrical environments.

By choosing Aparna Rollform’s ladder cable tray systems, businesses can ensure reliable cable management that meets the highest standards of performance and safety, even under heavy load conditions.