Modern electrical installations rely on organised cable systems to operate safely and perform consistently over time. Among the various cable support solutions available, perforated cable trays are widely preferred for their versatility, strength, and compliance with industry standards. From commercial buildings to industrial facilities, these trays offer an ideal balance between structural integrity and functional flexibility.

At Aparna Rollform, perforated cable trays are engineered to meet the evolving demands of electrical installations while adhering to stringent quality and safety standards.

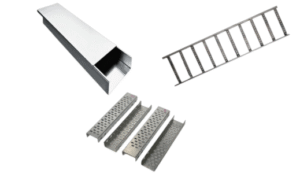

Understanding Perforated Cable Trays

Perforated cable trays are flat-bottomed trays featuring evenly spaced perforations across their surface. These perforations serve multiple purposes—reducing weight, improving ventilation, and allowing flexible cable routing and fastening.

Unlike solid trays, perforated trays provide better airflow and easier cable management, making them suitable for a wide range of electrical and data applications.

Importance of Standards in Electrical Projects

Compliance with industry standards is essential to ensure safety and performance in electrical installations. Perforated cable trays are designed and manufactured according to recognized standards that define material thickness, load capacity, finish, and dimensional accuracy.

Adhering to standards ensures:

- Safe support of power and control cables

- Compatibility with electrical codes

- Consistent performance under load

- Long-term durability

Aparna Rollform manufactures perforated cable trays with strict quality control processes to meet these essential requirements.

Strength and Load-Bearing Capability

A common misconception is that perforated trays compromise strength due to their cut-out design. In reality, well-engineered perforated cable trays offer excellent load-bearing performance when manufactured with appropriate material grades and thickness.

Key strength features include:

- Uniform load distribution across the tray surface

- Reinforced side flanges for added rigidity

- Optimized perforation patterns that maintain structural integrity

These features make perforated cable trays suitable for medium to heavy cable loads in most electrical projects.

Ventilation and Heat Management

Electrical cables generate heat during operation, especially in high-capacity systems. Excessive heat buildup can degrade insulation and reduce cable lifespan.

Perforated cable trays provide natural ventilation, allowing heat to dissipate efficiently. The perforations enable airflow while preventing dust accumulation, enhancing overall system safety and performance.

This makes them an ideal choice for:

- Power distribution systems

- Control panels

- Data and communication cabling

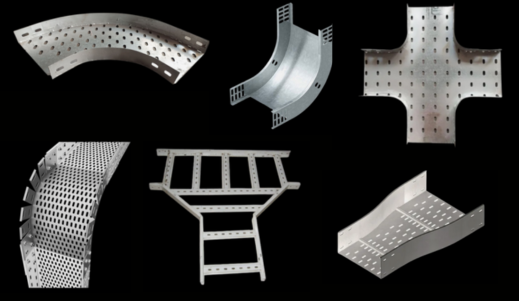

Flexibility in Cable Routing and Installation

One of the biggest advantages of perforated cable trays is their installation flexibility. The perforations allow easy fixing of cables using clamps or ties without additional drilling.

Installation benefits include:

- Faster and easier cable laying

- Simplified branching and directional changes

- Easy modifications during upgrades

This flexibility is especially valuable in projects that require frequent changes or expansions.

Durability and Corrosion Protection

Electrical projects often operate in environments exposed to moisture, dust, and industrial contaminants. Perforated cable trays from Aparna Rollform are available in multiple finishes, including:

- Pre-galvanized steel

- Hot-dip galvanized steel

- Powder-coated options

These finishes provide excellent corrosion resistance, ensuring long service life in both indoor and outdoor installations.

Applications of Perforated Cable Trays

Due to their balanced design and adaptability, perforated cable trays are widely used across various sectors, including:

- Commercial buildings

- Industrial plants

- Power substations

- IT and data centers

- Infrastructure and utility projects

They are suitable for supporting power cables, control cables, and communication wiring efficiently and safely.

Aparna Rollform’s Perforated Cable Tray Solutions

Aparna Rollform offers a comprehensive range of perforated cable trays designed to meet diverse project requirements. Our trays are manufactured using high-quality raw materials and advanced fabrication techniques to ensure:

- Reliable strength and stability

- Compliance with industry standards

- Ease of installation and maintenance

Each product is engineered to deliver consistent performance across demanding electrical environments.

Conclusion

Perforated cable trays play a vital role in modern electrical projects by combining strength, ventilation, and flexibility. Their compliance with industry standards, reliable load-bearing capacity, and ease of installation make them a preferred solution across commercial and industrial applications.

By choosing Aparna Rollform’s perforated cable trays, project owners and engineers can ensure efficient, safe, and durable cable management solutions that support long-term operational success.