In the modern construction industry, false ceilings have evolved from being a simple aesthetic element to an essential architectural component that enhances functionality, insulation, and design flexibility. Behind every flawless false ceiling lies a strong and reliable framework — and that’s where L-Angle and U-Angle sections play a transformative role.

These metal framing sections form the backbone of false ceiling systems, ensuring structural integrity, dimensional accuracy, and longevity. Made from high-quality galvanized steel, L-Angle and U-Angle sections are redefining how architects and contractors approach ceiling frameworks today.

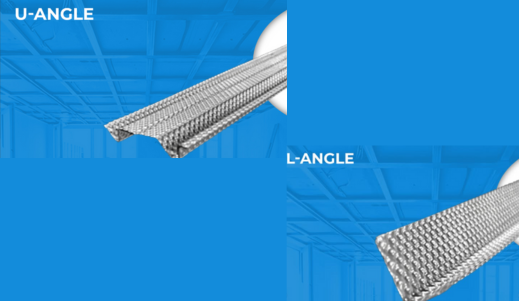

Understanding L-Angle and U-Angle Sections

L-Angle Sections

L-Angle sections, also known as Perimeter Angles or Edge Angles, are used to create the boundary structure along the walls in a false ceiling system. Their L-shaped cross-section allows them to support the ceiling grid, providing alignment and edge finishing.

Key Features:

- Acts as a support for ceiling tiles and channels.

- Provides clean edge definition along the wall.

- Easy to install and ensures a precise finish.

U-Angle Sections

U-Angle sections, with their U-shaped profile, serve as main runners or intermediate channels within the framework. They are designed to bear the load of ceiling materials and distribute weight evenly across the structure.

Key Features:

- Provides rigidity to the false ceiling structure.

- Supports suspension systems and ceiling tiles.

- Offers better load-bearing capacity and alignment accuracy.

Why Choose L-Angle and U-Angle Sections for False Ceilings?

1. Structural Stability

Both L-Angle and U-Angle sections offer excellent mechanical strength, ensuring the ceiling remains stable and crack-free even under long-term load conditions.

2. Dimensional Precision

Manufactured using roll-forming technology, these sections maintain uniform thickness, consistent shape, and precise dimensions — key factors in achieving flawless ceiling installations.

3. Corrosion Resistance

Galvanized steel sections are coated with a protective zinc layer, making them resistant to rust and corrosion, even in humid indoor environments.

4. Ease of Installation

Lightweight yet strong, these sections are easy to cut, align, and fix — reducing installation time and labor costs.

5. Compatibility and Design Flexibility

They seamlessly integrate with various ceiling materials — gypsum boards, acoustic tiles, PVC panels, and more — making them suitable for diverse architectural requirements.

6. Cost Efficiency

Their long life and low maintenance requirements make them a cost-effective choice for both residential and commercial projects.

Applications Across Sectors

L-Angle and U-Angle sections are versatile enough to be used across multiple industries:

- Residential Buildings: For smooth, aesthetic ceiling finishes.

- Commercial Spaces: Offices, malls, and retail outlets where design uniformity and durability are crucial.

- Educational Institutions: Ensuring safe and clean ceiling structures in classrooms and labs.

- Healthcare Facilities: Providing rust-resistant, hygienic frameworks suitable for hospitals.

- Industrial Units: Used in manufacturing areas for durable and stable ceiling grids.

How L-Angle & U-Angle Sections Are Redefining Modern Interiors

Modern architectural spaces demand sleek finishes, acoustic comfort, and energy efficiency — all achievable with well-engineered false ceiling systems.

By integrating L-Angle and U-Angle sections, builders can achieve:

- Superior load management for heavier ceiling materials.

- Enhanced design flexibility for customized interiors.

- Sustainable construction through recyclable steel usage.

- Long-term cost savings through reduced maintenance.

From minimalistic corporate interiors to luxurious residential ceilings, these sections are redefining what’s possible in interior framework engineering.

Conclusion

In every well-designed false ceiling, there’s an invisible framework holding everything together — and L-Angle and U-Angle sections form that backbone. Their strength, precision, and corrosion resistance make them an indispensable part of modern interior design.

By combining engineering excellence with aesthetic support, they ensure that every ceiling not only looks perfect but also performs reliably for years. Whether in homes, offices, or institutions, these sections continue to redefine ceiling frameworks for the future of modern architecture.