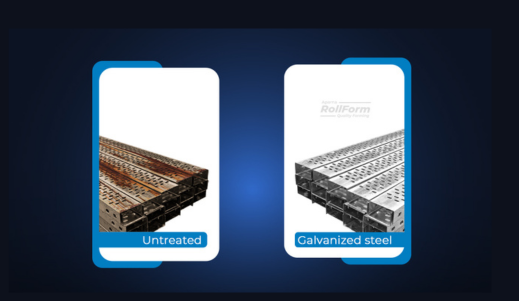

In an industrial landscape where the longevity and durability of materials are paramount, the galvanizing process stands as a cornerstone of metal protection. This transformative technique, which applies a protective zinc coating to steel, is crucial for extending the lifespan of metal structures and components across diverse applications. At Aparna Rollform, our commitment to delivering high-quality, resilient roll-formed products is deeply intertwined with the understanding and application of superior galvanization techniques.

This comprehensive guide explores the intricacies of the galvanizing process, detailing its critical steps and highlighting its immense importance in enhancing the performance and durability of metal products. We aim to provide a clear insight into why galvanization is not merely a coating but a fundamental engineering practice that ensures the long-term integrity of materials, aligning with Aparna Rollform’s dedication to precision and quality.

Unveiling the Process: A Step-by-Step Look at Galvanization

Galvanizing is a metallurgical process that involves applying a protective zinc coating to steel or iron to prevent rusting. The most common method, hot-dip galvanizing, involves immersing the fabricated steel in a bath of molten zinc. This process creates a metallurgical bond between the zinc and the steel, forming a series of zinc-iron alloy layers that are highly resistant to corrosion. The galvanizing process typically involves several key stages:

1. Surface Preparation: The Foundation of Adhesion

The success of the galvanizing process heavily relies on thorough surface preparation. This stage ensures that the steel surface is impeccably clean and free from contaminants, allowing for a strong and uniform bond with the zinc coating. Surface preparation typically involves three critical steps:

- Degreasing and Rinsing: The steel is first immersed in a degreasing solution to remove organic contaminants such as oil, grease, and dirt. This is followed by a thorough rinse to eliminate any residual degreasing solution.

- Pickling: To remove rust, mill scale, and other inorganic impurities, the steel is then submerged in an acidic solution, typically hydrochloric or sulfuric acid. This process leaves the steel surface chemically clean and ready for coating.

- Fluxing: The final preparation step involves dipping the steel into a flux solution, usually zinc ammonium chloride. This solution cleans the surface further, prevents oxidation before galvanizing, and promotes the metallurgical reaction between the steel and molten zinc.

2. Hot-Dip Galvanizing: The Core Transformation

Once the steel is meticulously prepared, it enters the heart of the process: the hot-dip galvanizing bath. The steel is immersed in a kettle containing molten zinc, maintained at a temperature of approximately 450°C (842°F). At this temperature, the molten zinc metallurgically reacts with the iron in the steel, forming a series of highly durable zinc-iron alloy layers, topped by a layer of pure zinc. The duration of immersion depends on the size and thickness of the steel component, ensuring a complete and uniform coating.

3. Cooling and Finishing: Ensuring Quality and Aesthetics

After removal from the molten zinc bath, the galvanized steel is cooled, either by quenching in water or by air cooling. This solidifies the zinc coating. Any excess zinc is removed, and the product undergoes a final inspection to ensure the coating thickness, adherence, and overall appearance meet the required specifications. This stage is crucial for verifying the quality and integrity of the galvanized product.

The Paramount Importance of Galvanizing

Galvanization is not merely a protective measure; it is an investment in the longevity and reliability of metal assets. Its importance is underscored by a multitude of benefits that directly impact the performance and cost-effectiveness of steel products:

1. Superior Corrosion Protection

The primary advantage of galvanizing is its exceptional ability to protect steel from corrosion. The zinc coating acts as a barrier, shielding the steel from environmental elements such as moisture, oxygen, and corrosive substances. Furthermore, zinc provides cathodic protection; if the coating is scratched or damaged, the surrounding zinc sacrificially corrodes to protect the exposed steel, preventing rust from spreading.

2. Extended Lifespan and Durability

By effectively preventing corrosion, galvanizing significantly extends the lifespan of steel products. Galvanized steel can withstand harsh weather conditions and aggressive environments for decades, reducing the need for frequent maintenance, repairs, or replacements. This extended durability translates into substantial long-term cost savings and enhanced structural integrity.

3. Cost-Effectiveness

While there is an initial cost associated with the galvanizing process, it proves to be highly cost-effective over the product’s lifecycle. The extended durability and reduced maintenance requirements of galvanized steel often result in lower overall expenses compared to other protective coatings that may require regular reapplication.

4. Comprehensive Protection

Hot-dip galvanizing ensures that all surfaces of the steel, including edges, corners, and recesses, are uniformly coated. This comprehensive coverage is difficult to achieve with other coating methods and is vital for protecting complex shapes and hard-to-reach areas from corrosion.

5. Ease of Inspection

The quality of a galvanized coating can be easily assessed visually and through simple non-destructive tests for thickness. This straightforward inspection process ensures that the product meets the required standards without complex and costly testing procedures.

Galvanizing in Today’s Industry: A Pillar of Modern Infrastructure

In an era of rapid infrastructure development and increasing demand for sustainable solutions, galvanizing plays a more critical role than ever. From construction and transportation to energy and telecommunications, galvanized steel is a material of choice for its reliability and environmental benefits. Its ability to provide robust, long-lasting protection makes it indispensable for projects that demand high performance and minimal maintenance.

At Aparna Rollform, we integrate the highest standards of galvanization into our manufacturing processes. Our products, including cable trays, earthing strips, and other roll-formed components, benefit from this superior protection, ensuring they deliver exceptional performance and durability in the most demanding environments. We understand that the strength of our products lies not just in their form but also in their ability to withstand the test of time and elements.

Conclusion: A Commitment to Enduring Quality

The galvanizing process is a testament to engineering ingenuity, offering a powerful and proven method for protecting steel from the relentless forces of corrosion. Its importance in modern industry cannot be overstated, as it contributes significantly to the safety, longevity, and cost-effectiveness of countless structures and systems worldwide. At Aparna Rollform, our dedication to quality means that every product we deliver is designed to endure, with galvanization being a key component of that promise. By choosing our galvanized roll-formed products, you are investing in a future of enhanced durability, reduced maintenance, and unwavering reliability.

For more insights into our manufacturing processes and the benefits of our galvanized products, we invite you to explore the Aparna Rollform website or connect with our technical experts. We are committed to providing solutions that build a stronger, more resilient future.