Why Quality False Ceiling Sections Matter in Large-Scale Projects

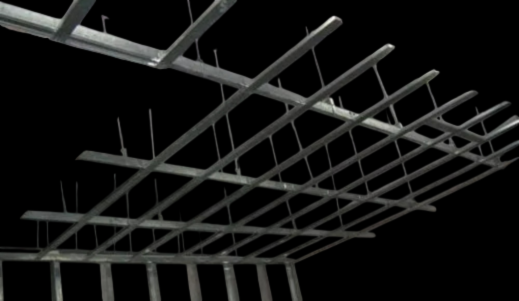

Blog Home / Blog / Why Quality False Ceiling Sections Matter in Large-Scale Projects Why Quality False Ceiling Sections Matter in Large-Scale Projects In large-scale construction projects, every component plays a critical role in determining long-term performance, safety, and aesthetics. False ceiling systems are often viewed as a finishing element, but in reality, they are a structural necessity that supports lighting, HVAC systems, fire safety equipment, and acoustic solutions. At the core of these systems lie high-quality false ceiling sections, which directly impact durability, alignment, and overall project efficiency. For large-scale projects such as commercial complexes, hospitals, airports, IT parks, and industrial facilities, choosing high-quality false ceiling sections is not optional—it is essential. The Role of False Ceiling Sections in Modern Construction False ceiling sections, including U-angle sections and ceiling channels, form the framework that holds ceiling panels and integrated services. They ensure stability, proper load distribution, and uniform alignment across wide ceiling spans. In large projects, ceilings must support: Lighting fixtures and electrical wiring HVAC ducts and diffusers Fire detection and suppression systems Acoustic and insulation materials Inferior-quality sections can lead to sagging, misalignment, and frequent maintenance issues, affecting both safety and appearance. Structural Strength and Load-Bearing Capability Large-scale projects demand ceiling systems that can handle continuous loads over extended areas. High-quality false ceiling sections are manufactured using precise roll-forming techniques and consistent material thickness to ensure strength and dimensional accuracy. Key benefits include: Uniform load distribution across long spans Resistance to bending and deformation Improved stability under suspended loads At Aparna Rollform, ceiling sections are engineered to perform reliably even in high-traffic and high-usage environments. Precision and Consistency Across Large Areas One of the biggest challenges in large-scale installations is maintaining consistency. Even minor variations in ceiling sections can result in uneven finishes, visible gaps, and alignment issues. Quality false ceiling sections offer: Accurate dimensions for seamless integration Clean edges for precise assembly Consistent profiles across batches This precision reduces on-site adjustments, speeds up installation, and ensures a flawless finish throughout the project. Durability and Corrosion Resistance False ceiling systems are often exposed to moisture, temperature fluctuations, and air-conditioning environments. Poor-quality materials can corrode over time, weakening the structure and increasing maintenance costs. Premium false ceiling sections are available with protective coatings that provide: Enhanced corrosion resistance Longer service life Reduced repair and replacement needs This durability is particularly important in hospitals, malls, and industrial facilities where ceilings are rarely accessible after installation. Faster Installation and Reduced Project Delays Time efficiency is crucial in large-scale projects with tight deadlines. High-quality false ceiling sections are designed for easy handling and quick installation. Advantages include: Better compatibility with standard ceiling systems Reduced wastage and rework Smooth integration with accessories and fittings Reliable ceiling sections help contractors complete installations faster without compromising quality. Safety and Compliance in Large Projects Safety regulations in large-scale construction are strict, especially in public and commercial buildings. False ceiling sections must meet structural and fire safety requirements to support integrated systems safely. Using certified, quality-tested ceiling sections ensures: Compliance with building codes Safe support for electrical and HVAC installations Reduced risk of ceiling failures This compliance protects both occupants and project stakeholders. Aesthetic Impact and Design Flexibility Beyond functionality, false ceilings play a key role in interior aesthetics. High-quality sections enable architects and designers to explore creative layouts without structural limitations. They support: Clean, modern ceiling designs Smooth integration of lighting and panels Long-term visual consistency Quality materials help the ceiling maintain its appearance over time. Aparna Rollform’s Commitment to Quality Ceiling Solutions Aparna Rollform manufactures false ceiling sections using advanced roll-forming technology and stringent quality controls. Our U-angle sections and ceiling channels are designed to deliver strength, precision, and durability for large-scale applications. By focusing on consistent performance and long-term reliability, Aparna Rollform supports construction projects that demand excellence at every level. Conclusion In large-scale projects, the success of a false ceiling system depends heavily on the quality of its core components. High-quality false ceiling sections ensure structural stability, faster installation, safety compliance, and lasting aesthetics. They reduce maintenance costs, improve project efficiency, and deliver a professional finish across expansive spaces. Choosing Aparna Rollform’s false ceiling sections means investing in reliable performance, precision engineering, and solutions built to stand the test of time. Related Blogs